Aluminum Door Hinge: Balancing Strength, Style, and Durability

1. The Often-Overlooked Hero in Every Door System

When we talk about doors, most people focus on design, color, or material — but the real unsung hero is the hinge. Without it, even the most beautiful aluminum door wouldn’t function at all. In modern architecture, where aluminum doors are becoming increasingly popular for both residential and commercial use, the aluminum door hinge plays a crucial role in ensuring long-term performance, safety, and smooth operation.

According to Grand View Research (2024), the global door hardware market was valued at USD 8.3 billion in 2023, with aluminum components accounting for more than 28% of total hardware usage. That number keeps growing as builders shift toward lightweight, corrosion-resistant materials — making aluminum door hinges a quiet but essential part of this transformation.

2. Why Aluminum? The Material Advantage

So why are aluminum hinges becoming the go-to choice for modern door systems?

Lightweight yet strong:

Aluminum’s density is roughly one-third that of steel — about 2.7 g/cm³ versus 7.8 g/cm³ — but when alloyed with elements like magnesium or silicon, it achieves impressive tensile strength (up to 300 MPa, depending on the alloy and temper). This makes it ideal for supporting medium to large door structures without adding unnecessary weight.

Corrosion resistance:

Unlike iron or steel, aluminum naturally forms an oxide layer that protects it from moisture and oxidation. With proper anodizing, this protection can last for decades — which is why aluminum hinges are widely used in coastal or humid regions where rust is a constant problem.

Aesthetic flexibility:

Aluminum also offers high flexibility in surface treatment — anodized matte finishes, powder coating, or electroplating — to match various architectural designs. It’s not just functional; it’s part of the door’s overall visual appeal.

3. The Role of Aluminum Door Hinges in Modern Architecture

In today’s building designs — whether minimalist villas or glass commercial façades — aluminum doors are synonymous with sleekness and functionality. But without the right hinge system, these doors can’t deliver stability, ease of use, or safety.

A high-quality door hinge for aluminum door does more than just connect; it distributes the door’s weight evenly, prevents sagging, and ensures smooth motion even after thousands of cycles.

According to European Hardware Association (EHA, 2023), a standard-grade residential door hinge should withstand at least 100,000 open-close cycles, while commercial-grade hinges may exceed 300,000 cycles.

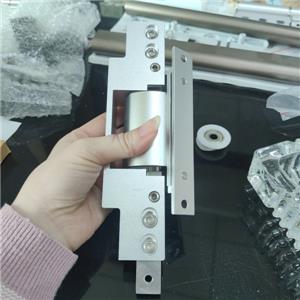

4. Types of Aluminum Door Hinges

Aluminum hinges come in various designs, each serving a different structural or aesthetic purpose. The most common types include:

Concealed hinges (hidden hinges): Perfect for modern minimalist aluminum doors, offering a clean look while maintaining high strength and easy adjustability.

Butt hinges: Traditional yet reliable, used in both interior and exterior aluminum door frames.

Continuous or piano hinges: Provide full-length support, ideal for tall or heavy aluminum doors that require additional stability.

Lift-off hinges: Allow quick door removal for cleaning or replacement, popular in commercial applications like hospitals or shopping centers.

Friction hinges: Enable adjustable resistance, ideal for doors or windows that need to stay in place at different angles.

Each hinge type can be made from pure aluminum or aluminum alloy, depending on the required load-bearing and environmental conditions.

5. Testing Standards and Durability

High-quality aluminum door hinges are manufactured according to international standards such as EN 1935 (Europe) and ANSI/BHMA A156.1 (North America). These standards define load capacity, corrosion resistance, and operational lifespan.

Durability tests usually include:

Cycle testing (number of opening and closing operations)

Salt spray testing (for corrosion resistance, usually 48–96 hours under ASTM B117 conditions)

Load testing (ensuring hinge deformation stays within acceptable limits under full door weight)

Although some factories — such as small OEM suppliers — may not have in-house salt spray testing equipment, they typically outsource testing to certified third-party laboratories to ensure compliance with export standards.

6. Function Meets Design — The Modern Aesthetic of Hinges

Once hidden behind door frames, hinges are now becoming part of the design language. Many architects and interior designers are intentionally exposing brushed aluminum hinges to highlight craftsmanship and mechanical precision.

In high-end applications — like luxury villas or boutique hotels — concealed hinges with adjustable 3D settings are particularly favored because they allow perfect alignment while remaining invisible when the door is closed.

7. Market Growth and Industry Insights

The aluminum door hinge market is closely tied to the global aluminum door and window industry.

According to Mordor Intelligence (2024), the aluminum doors and windows market is projected to grow at a CAGR of 5.8% from 2024 to 2030, driven by urbanization, sustainable building policies, and rising demand for energy-efficient materials. As this happens, demand for compatible hardware — especially aluminum hinges — naturally follows.

Meanwhile, the Asia-Pacific region (particularly China) dominates both manufacturing and export. China alone accounts for over 45% of global aluminum hardware exports (source: UN Comtrade, 2023), supplying markets in the Middle East, Europe, and Africa.

8. OEM and ODM Collaboration — The Backbone of Supply Chains

In the international market, many door hinge suppliers operate under OEM (Original Equipment Manufacturer) or ODM (Original Design Manufacturer) models.

These partnerships allow overseas brands to customize hinge shapes, surface finishes, and packaging while leveraging China’s efficient production capabilities.

Companies like WSMT, for example, provide professional OEM and ODM aluminum door hinges for international customers. While they don’t perform in-house salt spray testing, they ensure product quality through outsourced third-party verification and strict material selection. This approach maintains flexibility while meeting export standards.

9. Sustainability and Environmental Considerations

Aluminum’s recyclability is one of its strongest environmental advantages.

According to The Aluminium Association (2024), using recycled aluminum saves up to 95% of the energy compared to primary production. Many modern hinge manufacturers now use up to 60–80% recycled aluminum in their products — reducing carbon footprint without compromising strength or durability.

As green building certifications (like LEED and BREEAM) become global benchmarks, aluminum door hinges made from recycled materials are increasingly preferred by architects and developers aiming for sustainable projects.

10. The Future of Aluminum Door Hinges

The future of aluminum door hinges lies in innovation and integration.

We’re already seeing trends like:

Smart hinge systems with built-in dampers or motion sensors;

Modular hinge kits for faster installation;

Custom surface coatings for improved corrosion resistance in marine climates.

In the coming years, the fusion of mechanical precision, material science, and design aesthetics will continue to redefine what a “hinge” can be — transforming it from a basic connector into a true component of modern architecture.

A Thought to Close

The humble aluminum door hinge might not be the centerpiece of a building, but it’s what makes the entire structure functional and reliable. Every smooth swing of an aluminum door, every secure closure, and every year of trouble-free use — all begin with the quality of the hinge behind it.

So next time you open a sleek aluminum door, remember: the smallest part often carries the biggest responsibility.