China Aluminum Casement Handle: The Rising Standard in Window Hardware

In today’s architectural world, the small details often make the biggest difference. One such underrated hero in window systems is the aluminum casement handle — a product that perfectly blends functionality, aesthetics, and durability. Over the last decade, China aluminum handle suppliers have gained global recognition for their balance of quality and cost-effectiveness. Whether you’re designing a modern home or sourcing for a large construction project, understanding the market for aluminum window hardware can make your choices smarter and more profitable.

1. Why Aluminum Handles Are Taking Over the Market

Aluminum has long been a preferred material in architecture due to its lightweight strength and corrosion resistance. When used for casement window handles, it provides an ideal balance between sturdiness and smooth operation.

According to Grand View Research (2024), the global aluminum door and window market was valued at over USD 70 billion in 2023 and is expected to grow at a CAGR of 5.2% through 2030. Much of this growth is driven by residential and commercial renovation projects that emphasize energy-efficient and durable materials. Handles, though small, play a critical role in user experience and long-term performance.

Architects and designers now prioritize hardware that’s not only functional but also ergonomic and minimalistic. The smooth grip, sleek surface finish, and easy locking mechanism of the aluminum casement handle align perfectly with these expectations.

2. Understanding the Casement Handle Design

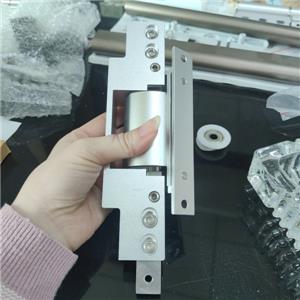

Casement handles are specifically designed for outward- or inward-opening windows. They are typically mounted on the sash and linked to a locking system that ensures airtight sealing when closed.

High-quality China aluminum handles are now available in a variety of finishes such as matte silver, powder-coated black, anodized bronze, and brushed gold, giving homeowners more freedom to match their windows with interior themes. The best designs focus on:

Smooth torque operation: Prevents the handle from feeling stiff over time.

Durable spindle material: Usually stainless steel or zinc alloy to avoid wear.

Adjustable mounting holes: Fits multiple window frame profiles.

Corrosion-resistant coatings: Extends service life even in coastal or humid regions.

Chinese factories have significantly improved molding precision and surface treatment over the past five years, allowing them to produce handles that meet European EN standards and American ASTM requirements.

3. Global Market Trends in Aluminum Window Hardware

The window handle manufacturer sector has evolved alongside architectural trends. Mordor Intelligence (2024) reports that Asia-Pacific holds over 45% of the global aluminum window hardware market, largely thanks to strong exports from China, India, and Vietnam.

China remains the largest exporter of aluminum casement handles, shipping products to over 120 countries, including the UAE, Saudi Arabia, Germany, the UK, and Australia. The reason is simple — Chinese manufacturers combine scalable OEM/ODM capabilities with cost-effective production.

European brands often source semi-finished handles from Chinese OEM plants, then apply localized branding and packaging. This cooperative model benefits both sides — Western companies get reliable supply chains, and Chinese suppliers expand their global presence.

4. What Makes China Aluminum Handles Competitive

There’s no denying that “Made in China” products used to face skepticism for quality. But that perception has changed dramatically. Over the last decade, Chinese window hardware factories have invested heavily in CNC machining, die-casting automation, and quality control management systems.

Some reasons behind China’s competitive edge include:

Efficient supply chains: China’s aluminum extrusion and anodizing industries are among the most developed globally.

OEM/ODM flexibility: Factories easily adapt to new mold designs or branding requests.

Cost-performance ratio: Even with higher logistics costs post-2020, the average export price for an aluminum casement handle remains 15–25% lower than similar European models (Source: Statista, 2024).

Production clustering: Regions like Guangdong, Zhejiang, and Jiangsu have industrial clusters specializing in door and window hardware, ensuring efficient component sourcing.

5. The Rise of Minimalist and Smart Handle Designs

Design preferences have also shifted. More architects and homeowners want handles that are minimalist, smooth-edged, and integrated with the overall window system. Some window handle manufacturers are now offering smart lock options — where aluminum handles integrate electronic locking, touch sensors, or RFID activation.

According to a 2024 survey by Houzz, over 32% of homeowners planning renovations said they prefer sleek,modernwindow hardware with soft finishes. This explains the popularity of matte anodized aluminum over traditional chrome-plated handles.

Chinese OEM factories are already producing smart-compatible aluminum window handles for European and Middle Eastern brands, showing how fast the market is moving toward automation and user comfort.

6. Comparing China’s Products with European and American Handles

When comparing China aluminum handle products with Western counterparts, several differences appear — not necessarily in quality, but in price-to-performance and customization flexibility.

| Feature | China Aluminum Handle | European Handle | American Handle |

|---|---|---|---|

| Price (avg.) | 15–25% lower | Higher due to labor & branding | Mid-range |

| Customization | OEM/ODM friendly | Limited to specific models | Limited |

| Design flexibility | High (accepts custom moldings) | Standardized | Moderate |

| Compliance | CE, ISO, RoHS available | CE-certified | ANSI-certified |

While European brands still dominate premium architecture projects, the global mid-range market is largely supplied by Chinese window hardware manufacturers, offering balanced performance and customizable options.

7. The Role of OEM & ODM in the Handle Industry

For global importers, the OEM/ODM model is essential. Many buyers approach Chinese window handle manufacturers with their own logo and package design. Chinese factories typically support this with low minimum order quantities (MOQ) and custom mold design services.

However, it’s important to note that not all factories have in-house testing equipment like salt-spray chambers or tensile test machines. Many rely on third-party labs (e.g., SGS, TÜV, Intertek) for performance testing to meet export standards.

This setup works well for buyers seeking private-label partnerships without investing in their own production lines. It’s a win-win situation: Chinese suppliers expand their portfolio, and overseas distributors maintain brand exclusivity.

8. Common Questions from International Buyers

To make the buying process smoother, let’s go through some frequently asked questions from importers and project managers.

Q1: What’s the typical lead time for aluminum casement handles?

Usually 25–35 days after order confirmation, depending on mold availability and finish requirements.

Q2: Can I request custom anodized colors or engravings?

Yes. OEM factories can do custom RAL colors and laser-engraved logos with low MOQ.

Q3: How do I verify product quality before shipment?

Most buyers hire third-party inspection companies or request video inspection before packaging.

Q4: Are Chinese handles suitable for coastal areas?

Yes, if the product uses marine-grade anodizing (AA15–AA25) or powder coating. Always confirm coating specs before placing bulk orders.

9. The Future Outlook of Aluminum Casement Handles

Looking ahead, the aluminum window hardware market is expected to evolve toward energy efficiency, minimalistaesthetics, and smart integration. As green construction and sustainable materials gain traction, aluminum will remain the metal of choice due to its recyclability and lightweight durability.

According to Statista (2025), the global smart window hardware market could surpass USD 3.5 billion by 2031, and aluminum will account for nearly 60% of that share.

For China’s manufacturers, the focus will likely stay on OEM/ODM partnerships, rather than developing proprietary brands. This keeps production flexible and responsive to global trends.

10. Final Thoughts

The rise of the China aluminum handle industry isn’t just about low cost anymore. It’s about consistency,customization, and modern design. From advanced anodizing techniques to ergonomic handle curves, Chinese factories have mastered the art of balancing form and function.

For architects, traders, and distributors worldwide, sourcing aluminum casement handles from China now means getting products that look great, perform reliably, and fit your market’s needs — all while staying price-competitive.

The next decade will belong to brands and OEM partners that understand this synergy between design, material, and market rhythm — and that’s exactly where China stands strong today.