China Aluminum Casement Handle: The Smart Choice for Quality and Affordability

Walk into any modern home, office, or hotel, and you’ll notice one common element — sleek aluminum windows with elegant, ergonomic handles. These aren’t just design details; they’re essential components that ensure smooth operation, safety, and long-term durability.

And when it comes to sourcing these components, China aluminum casement handle products have become one of the most trusted options globally. Affordable yet durable, stylish yet functional — it’s no wonder that more architects, builders, and distributors are choosing handles made in China.

In this article, we’ll explore what makes Chinese aluminum casement handles stand out, how they compare with other regions’ products, and why the right handle can make a big difference in window performance and user experience.

1. What Is a Casement Handle and Why Does It Matter?

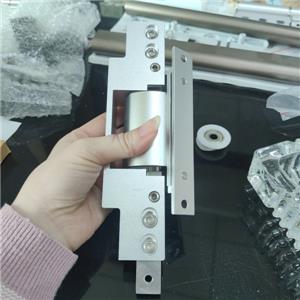

A casement handle (or window handle) is a small but vital part of an aluminum window system. It allows users to open, close, and lock the sash smoothly, while ensuring airtightness and security.

A good aluminum window handle must balance design, strength, and comfort. It needs to withstand thousands of open-close cycles while maintaining its shape, finish, and mechanical integrity.

According to Mordor Intelligence (2024), the global aluminum window and door hardware market is expected to reach USD 13.7 billion by 2030, growing at a CAGR of 5.6%. A large part of that growth is driven by the increasing demand for energy-efficient and low-maintenance aluminum windows — all of which rely heavily on durable, precision-made handles.

2. Why China Aluminum Casement Handle Leads the Market

China has become the world’s largest production hub for aluminum window hardware, including casement handles. There are three main reasons for this dominance:

(1) Cost efficiency with quality control

Chinese aluminium handle manufacturers have perfected mass production techniques that allow for competitive pricing without compromising performance. Modern CNC machining centers, die-casting equipment, and surface finishing lines ensure tight tolerances and uniform quality.

(2) Flexibility for OEM / ODM projects

Many Chinese factories operate as OEM aluminum handle suppliers for global brands. This means they can customize everything — from design, shape, color, to branding — according to client requirements.

(3) Strong global supply chain

Ports like Ningbo, Foshan, and Shanghai enable fast global shipping. Combined with export experience, this allows Chinese suppliers to deliver consistent quality at scale to Europe, the Middle East, and North America.

According to China Nonferrous Metals Industry Association (2024), China exported over USD 3.4 billion worth of aluminum window and door accessories in 2023, a number that continues to grow each year.

3. Common Types of Aluminum Casement Handles

Let’s look at the main handle categories you’ll find in the market:

| Handle Type | Description | Typical Use |

|---|---|---|

| Espagnolette Handle | Multi-point locking handle, easy to operate | High-end casement windows |

| Crescent Handle | Simple lock handle with a curved latch | Residential windows |

| Friction Handle | Allows partial opening with friction stay support | Ventilation windows |

| Slimline Handle | Minimalist look, designed for modern interiors | Slim-frame aluminum systems |

Each handle type has its own mechanical requirements and mounting standards. Most Chinese suppliers can produce all four, often using ADC12 aluminum alloy for high strength and corrosion resistance.

4. How Aluminum Compares with Other Materials

When it comes to window hardware, materials matter. Here’s how aluminum handles stack up against others:

| Property | Aluminum | Zinc Alloy | Stainless Steel | Plastic |

|---|---|---|---|---|

| Strength-to-weight ratio | High | Medium | Very high | Low |

| Corrosion resistance | Excellent | Good | Excellent | Poor |

| Cost | Medium | Low | High | Low |

| Recyclability | 100% | 60% | 90% | 10% |

| Design flexibility | Very high | Medium | Low | High |

It’s clear why the China aluminum casement handle is favored globally — it offers the best balance between durability, appearance, and price.

5. Surface Treatment and Finishing

A key feature that defines handle quality is surface finishing. Common processes include:

Anodizing – Enhances corrosion resistance, available in silver, champagne, or black.

Powder Coating – Provides color flexibility and UV protection.

Electrophoresis (E-coating) – Creates a smooth, uniform surface for premium products.

Brushing and Polishing – Adds a tactile, metallic texture for luxury applications.

According to European Aluminium Association (2024), anodized aluminum can last 20–25 years outdoors without significant fading, provided the coating thickness is above 15 µm.

6. The Rise of Ergonomic and Smart Handle Design

Modern aluminum window handle design focuses not just on looks, but also on comfort and safety.

Ergonomic Curves: Improve grip and user comfort.

Child Safety Locks: Prevent accidental opening in high-rise apartments.

Smart Handle Integration: Some manufacturers now integrate IoT sensors that notify users if a window is left open — a trend expected to grow rapidly in Europe and the U.S.

Smart Home Market Research (2024) projects that by 2028, over 12% of new aluminum windows sold in the EU will include some form of connected hardware, including handles.

7. Understanding OEM and ODM in Handle Manufacturing

Most aluminium handle manufacturers in China operate on OEM (Original Equipment Manufacturer) or ODM (Original Design Manufacturer) bases.

This means international brands can order handles:

Designed from scratch based on custom CAD drawings (ODM), or

Branded versions of existing models (OEM).

OEM/ODM flexibility is one of China’s greatest strengths. A company can order 10,000 handles with its own logo, color, and packaging — and receive them within 4–6 weeks.

It’s a key reason why even European brands rely on OEM aluminum handle suppliers from China to maintain cost efficiency while preserving brand image.

8. Environmental Impact and Sustainability

Aluminum is one of the world’s most sustainable metals. According to World Aluminium (2024), over 75% of allaluminum ever produced is still in use today because of its recyclability.

Producing recycled aluminum requires 95% less energy than producing new aluminum. Many Chinese factories have started integrating recycled ingots into their handle production to align with global sustainability goals and LEED-certified building projects.

9. How to Choose the Right Handle for Your Project

When choosing a China aluminum casement handle, consider:

Window type – outward opening, top-hung, or side-hung.

Finish – anodized, powder-coated, or brushed.

Locking system – single-point or multi-point.

Usage environment – coastal (needs higher corrosion resistance) or inland.

Style – match handle design with frame aesthetics.

If you’re sourcing for a project, always request:

Product drawings

Material certification (e.g., ADC12, 6063-T5)

Coating thickness reports

Sample tests before bulk production

10. China vs. Europe: Performance and Price

European window hardware is known for precision and design innovation, but it often costs 30–50% more than Chinese equivalents.

A 2023 report from Statista noted that China’s average export price for aluminum window handles was USD 1.80–3.50 per piece, compared to USD 5–8 for European-manufactured models.

However, the quality gap is rapidly narrowing. Many China aluminum casement handle suppliers now comply with EN 13126-3 and ISO 9001:2015 standards, ensuring durability and consistent performance.

11. Challenges and Opportunities in the Industry

Despite its advantages, the industry faces some challenges:

Price competition can lead to low-cost, low-quality copies.

Environmental regulations are tightening, requiring cleaner production.

Global logistics costs fluctuate, affecting export margins.

On the flip side, opportunities abound:

The Middle East and Africa markets are rapidly expanding, fueled by new construction.

The smart window trend is creating new demand for electronically integrated handles.

Partnerships with overseas distributors are growing — especially for ODM lines.

12. Customer FAQs

Q1: How long can an aluminum handle last?

A: Typically 15–25 years, depending on the finish and usage. Anodized handles last longest.

Q2: Can I customize the color or logo?

A: Yes, most Chinese manufacturers support custom powder coating and laser engraving.

Q3: Are Chinese handles safe for high-end projects?

A: Absolutely. Many OEM aluminum handle suppliers serve European and Australian markets where safety standards are strict.

Q4: What’s the minimum order quantity?

A: Usually 500–1000 pieces per model, depending on customization level.

13. Looking Ahead — Where the Market Is Going

The future of China aluminum casement handle production lies in smart functionality, sustainability, and better design.

More eco-friendly coatings will reduce VOC emissions.

Smart lock systems will sync with home automation apps.

Lightweight alloys and minimalist aesthetics will define next-gen window hardware.

As global construction moves toward green and digital transformation, Chinese handle suppliers are well-positioned to meet new expectations — not just as manufacturers, but as collaborative design partners for international brands.

Final Thoughts

Choosing the right aluminum window handle isn’t just about finding the cheapest option — it’s about choosing reliability, comfort, and sustainability.

China’s hardware industry continues to refine its balance between craftsmanship and cost-effectiveness, and that’s exactly why the China aluminum casement handle remains a smart, future-ready choice for architects, homeowners, and distributors around the world.