The Future of the Aluminium Door and Window Industry: Trends, Innovations, and Strategic Directions

The global window and door industry has undergone a significant transformation over the past decade. Among the most dynamic segments of this sector is the aluminium door and aluminum window and door market. This niche continues to grow in response to global trends such as urbanization, sustainability mandates, technological innovation, and consumer preferences for modern, durable, and energy-efficient products. As 2025 progresses, it becomes increasingly clear that the aluminium segment is setting the standard for performance and innovation in the building materials market.

A Global Industry on the Rise

The window and door industry is estimated to be worth over $180 billion globally, with aluminium-based products accounting for a substantial and growing share. Aluminium’s combination of lightweight durability, corrosion resistance, and aesthetic flexibility makes it the material of choice in both residential and commercial architecture.

In particular, the demand for aluminium door systems has grown as architects and developers prioritize sleek, minimalist designs that do not compromise on strength or thermal performance. Similarly, aluminum window and door systems are increasingly preferred for large-scale glazing, offering panoramic views and enhanced natural lighting — especially valuable in high-end residential and hospitality construction.

Drivers of Growth in the Aluminium Segment

1. Urbanization and Infrastructure Development

Rapid urban development, particularly in Asia, the Middle East, and parts of Africa, has driven increased demand for modern construction solutions. Aluminum window and door products are well-suited to the high-rise and mid-rise buildings common in new urban centers. Their high strength-to-weight ratio allows for larger openings and more glass, supporting architectural freedom without sacrificing performance.

2. Sustainability and Energy Efficiency

Sustainability is no longer optional — it is a baseline requirement across the construction industry. Aluminium, despite the high energy consumption in its primary production, is 100% recyclable without degradation of properties. In fact, the majority of aluminium door and aluminum window and door systems today include a high percentage of recycled content.

Moreover, advances in thermal break technology and multi-chamber frame designs have drastically improved the energy efficiency of aluminium products. These enhancements help builders meet stringent energy codes and reduce the carbon footprint of buildings over their lifecycle.

3. Design Flexibility and Aesthetics

Modern architecture favors large spans, open floor plans, and minimal framing — all of which are supported by aluminium systems. Powder coating and anodizing techniques also allow aluminium frames to be customized in an endless range of finishes and textures. As homeowners and developers seek distinctive yet durable solutions, aluminium door and window products are emerging as the go-to option.

4. Technological Advancements

The adoption of smart technologies and automation is also impacting the window and door industry. Many manufacturers are now offering integrated smart locks, sensors, and automated opening systems that sync with home management systems. Aluminium systems are especially adaptable to such innovations due to their structural integrity and compatibility with motorized hardware.

Additionally, precision manufacturing techniques, including CNC machining and robotic assembly, have enhanced the consistency and performance of aluminum window and door products, reducing waste and improving quality assurance.

Regional Trends and Market Dynamics

North America

In North America, there has been a notable shift from wood and vinyl to aluminium products, particularly in commercial and high-end residential sectors. Stringent energy codes, combined with consumer demand for low-maintenance and modern-looking solutions, are pushing the market further toward thermally broken aluminium door and window systems.

Europe

Europe continues to lead in sustainable design and energy efficiency, which naturally aligns with aluminium’s capabilities. Markets such as Germany, the UK, and the Nordics have seen rising demand for passive house-certified aluminum window and door solutions. Moreover, European regulations have fostered innovation in recyclable components and modular system designs.

Asia-Pacific

China, India, and Southeast Asia represent the fastest-growing regional markets. Massive infrastructure and housing initiatives, especially in urban and peri-urban zones, are driving record-level installations of aluminium products. Local manufacturers are increasingly aligning with international standards, promoting export opportunities and technological exchange within the global window and door industry.

Innovations Shaping the Future

Several innovations are poised to further transform the aluminium window and door industry in the coming years:

Vacuum-Insulated Glazing (VIG): These ultra-thin, high-performance glass units complement the thermal performance of aluminium frames and enable even slimmer profiles.

Modular Fabrication Systems: Prefabricated aluminium modules are reducing construction time and increasing installation accuracy, particularly in high-density residential projects.

Circular Economy Solutions: More manufacturers are implementing take-back and recycling programs for old aluminium door and window units, promoting cradle-to-cradle material lifecycles.

BIM Integration: Building Information Modeling (BIM) is allowing specifiers to model and simulate aluminum window and door systems with unprecedented precision, improving design outcomes and cost forecasting.

Challenges Facing the Industry

Despite its strong trajectory, the aluminium segment of the window and door industry faces several challenges:

Supply Chain Vulnerabilities: Aluminium production is sensitive to geopolitical factors, particularly energy costs and trade policies affecting bauxite and alumina sourcing.

Cost Competitiveness: While aluminium offers many performance benefits, it remains more expensive than alternatives like vinyl and wood. Bridging this gap through economies of scale and process efficiencies is a key industry focus.

Labor Shortages: Like many sectors in construction and manufacturing, the window and door industry faces a shortage of skilled labor, particularly in fabrication and installation. This is prompting increased investment in training programs and automation.

Strategic Goals for 2025 and Beyond

To remain competitive and sustainable, players in the aluminum window and door sector are pursuing several key strategic directions:

Decarbonization: Companies are working toward carbon-neutral aluminium production by transitioning to renewable energy sources and investing in carbon capture technologies.

Product Standardization: Harmonizing performance and testing standards across international markets will enable smoother trade and increase consumer confidence in aluminium door systems.

Vertical Integration: Leading firms are expanding their control over the supply chain, from raw materials to finished systems, ensuring quality and supply resilience.

Digital Transformation: Embracing data-driven manufacturing, AI-driven design optimization, and digital customer interfaces is becoming essential for future growth.

Conclusion

The aluminium door and aluminum window and door market is no longer a niche — it is at the forefront of the global window and door industry. With its unmatched blend of durability, sustainability, and design adaptability, aluminium continues to meet the evolving demands of architects, developers, and end-users alike.

As the industry adapts to economic, environmental, and technological shifts, innovation and collaboration will be essential. Whether through smart automation, improved thermal performance, or closed-loop manufacturing, the future of the window and door industry is being built — quite literally — through aluminium.

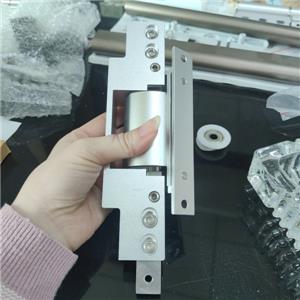

At the heart of these advancements, WSMT is dedicated exclusively to the development and manufacturing of precision-engineered components for aluminium doors and windows. From high-performance hinges and locks to advanced sliding systems, WSMT brings deep expertise and strict quality control to every product we deliver. If you're building with aluminium, we make sure the details perform as beautifully as the design.